The advantages of nylon PA66 glass fiber reinforced in household appliances

Time:2022-08-04 16:15:05 Click:

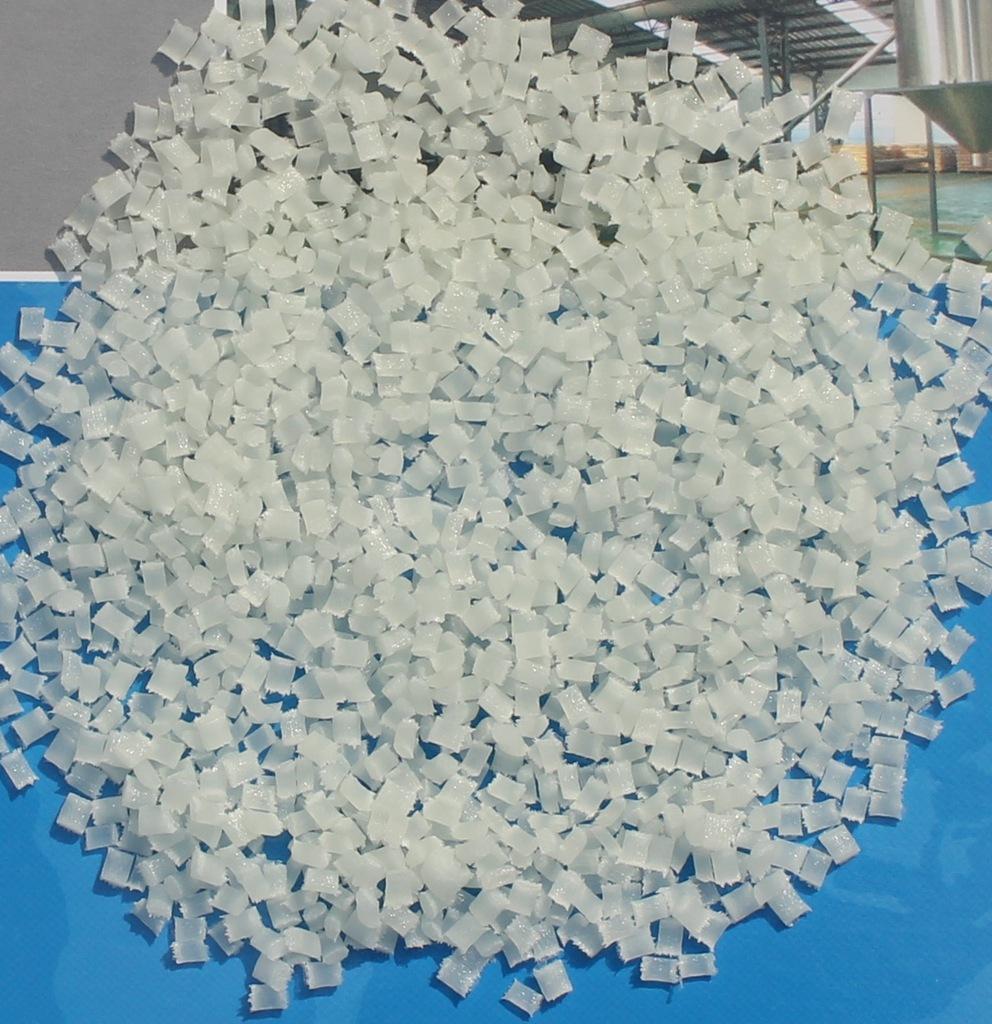

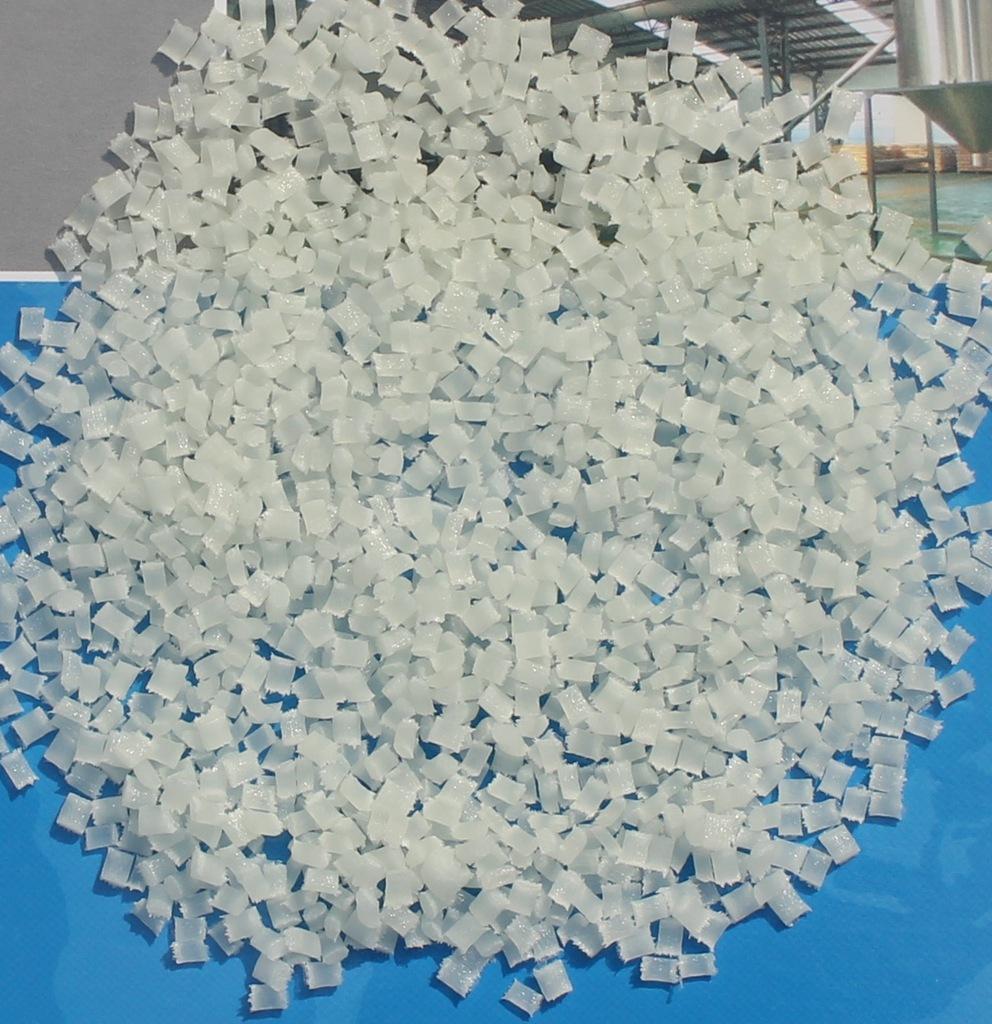

Glass fiber reinforced PA66 is usually used in the mouthpieces of high-quality hair dryers, which can improve the compressive strength and improve the ability to work in heat.However, with the increasing requirements for the basic functions of hair dryers, ABS, which was originally the main raw material of the casing, was gradually replaced by glass fiber reinforced PA66.

At this stage, the main factors affecting the production of glass fiber reinforced PA66 composite materials with excellent performance include the length of glass fiber, the surface solution of glass fiber, and the length of storage in the substrate.

When fiber is reinforced, the length of the fiber is one of the primary factors in determining the fiber-reinforced composite material.In ordinary short fiber reinforced thermoplastics, the fiber length is only (0.2~0.6) mm, so when the bearing capacity of the raw material is destroyed, the compressive strength is usually not used because of the short length of the fiber, and fiber reinforcement is used.The goal of polyester is to use the high stiffness and high toughness of the fiber to improve the physical properties of polyester, so fiber length has a key effect on the physical properties of the product.Compared with the short glass fiber reinforced method, the elastic modulus, compressive strength, stress relaxation resistance, fatigue resistance, impact resistance, temperature resistance, and wear resistance of long glass fiber reinforced polyester have all been improved.It is used in vehicles, household appliances, machinery and other industries.

The bonding between the glass fiber and the substrate is another key factor that endangers the physical properties of the composite.Glass fiber reinforced polymers can only have good properties if they produce efficient page bonding.For glass fiber reinforced thermosetting resin or positive and negative thermoplastic resin composite materials, silane coupling agent can be used to solve the surface of glass fiber, so that epoxy resin and glass fiber surface can generate ionic bond, and then efficient page bonding can be obtained.

We have carried out a large-scale scientific research on the mixing of glass fiber reinforced thermoplastic resin and the product forming process, and found that the length of glass fiber in the product is limited to within 1mm from beginning to end, which is greatly reduced compared with the original fiber length.Subsequently, scientific research was carried out on the state of fiber rupture during the production process, and it was found that the production process standards and various other factors were harmful to the fiber rupture.

When fiber is reinforced, the length of the fiber is one of the primary factors in determining the fiber-reinforced composite material.In ordinary short fiber reinforced thermoplastics, the fiber length is only (0.2~0.6) mm, so when the bearing capacity of the raw material is destroyed, the compressive strength is usually not used because of the short length of the fiber, and fiber reinforcement is used.The goal of polyester is to use the high stiffness and high toughness of the fiber to improve the physical properties of polyester, so fiber length has a key effect on the physical properties of the product.Compared with the short glass fiber reinforced method, the elastic modulus, compressive strength, stress relaxation resistance, fatigue resistance, impact resistance, temperature resistance, and wear resistance of long glass fiber reinforced polyester have all been improved.It is used in vehicles, household appliances, machinery and other industries.

The bonding between the glass fiber and the substrate is another key factor that endangers the physical properties of the composite.Glass fiber reinforced polymers can only have good properties if they produce efficient page bonding.For glass fiber reinforced thermosetting resin or positive and negative thermoplastic resin composite materials, silane coupling agent can be used to solve the surface of glass fiber, so that epoxy resin and glass fiber surface can generate ionic bond, and then efficient page bonding can be obtained.

We have carried out a large-scale scientific research on the mixing of glass fiber reinforced thermoplastic resin and the product forming process, and found that the length of glass fiber in the product is limited to within 1mm from beginning to end, which is greatly reduced compared with the original fiber length.Subsequently, scientific research was carried out on the state of fiber rupture during the production process, and it was found that the production process standards and various other factors were harmful to the fiber rupture.

PRE:Back to list

NEXT:Back to list