How does glass fiber reinforced nylon PA6 raw material play its own strengths?

Time:2022-08-05 17:52:58 Click:

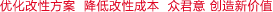

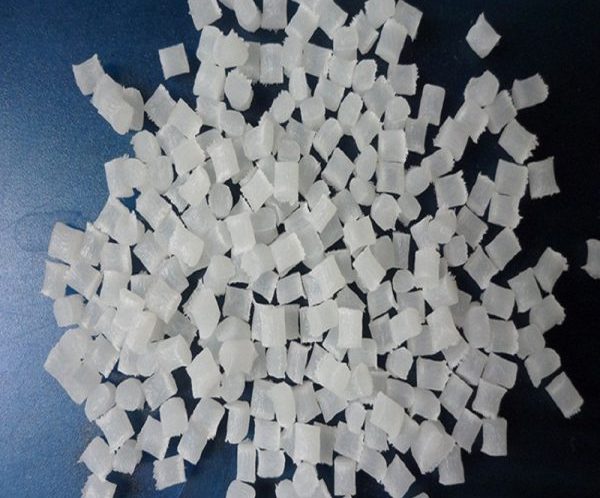

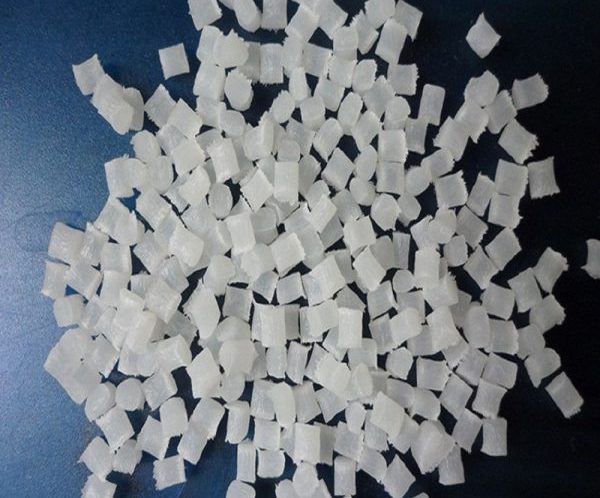

Generally speaking, glass fiber reinforced nylon 6 material is to add 10% to 50% glass fiber and some additives to the pure nylon material, which effectively improves the performance of glass fiber reinforced nylon 6 and greatly expands the glass fiber reinforced nylon 6.scope of application.

However, as a structural part of many products, glass fiber reinforced nylon 6 has some advantages.

Let's take a look at how glass fiber reinforced nylon 6 should play the advantages of the material.However, the temperature resistance of glass fiber reinforced nylon 6 is improved, and the production ambient temperature is also increased by 20 to 40 °C; but the shrinkage rate will drop from 1.5 to 0.3%.

One is that the impact performance of glass fiber reinforced nylon 6 materials will be improved.Some glass fiber reinforced nylon 6 surface cracks are not prone to occur.

One is that the tensile mechanical properties of glass fiber reinforced nylon 6 are improved, but there are several shortcomings: the existence of the candle wick effect will reduce the flame retardant performance.

Second: the appearance and transparency of glass fiber reinforced nylon 6 decrease, and the problem of floating fiber affects the use of glass fiber reinforced nylon 6.

Third: the processing performance of glass fiber reinforced nylon 6 will drop sharply, the fluidity will become very poor, and the injection pressure will increase a lot compared to when no glass fiber is added.When the fiber is used, it should be increased by 10°C to 30%°C.

But how to take advantage of glass fiber reinforced nylon 6 in injection molding: the glass fiber diameter of glass fiber reinforced nylon material is generally controlled between 10 and 20 microns.

Second: some coupling agents can be added appropriately, so that the impact strength of the notch can be increased with the increase of coupling agents.

Third: It can eliminate some moisture on the surface of glass fiber reinforced nylon 6, and then some hydrolysis reactions generated by glass fiber reinforced nylon 6 can be degraded during the melt extrusion process, thereby effectively reducing the glass fiber reinforced nylon 6 material.mechanical properties.

Fourth: But you can also control the length of the glass fiber, generally it is better to control it at 2 to 3 mm.

The longer the glass fiber reinforced nylon 6, the better the material properties, but the surface of the glass fiber reinforced nylon 6 material is rougher., but the warping problem is more difficult to control.

However, as a structural part of many products, glass fiber reinforced nylon 6 has some advantages.

Let's take a look at how glass fiber reinforced nylon 6 should play the advantages of the material.However, the temperature resistance of glass fiber reinforced nylon 6 is improved, and the production ambient temperature is also increased by 20 to 40 °C; but the shrinkage rate will drop from 1.5 to 0.3%.

One is that the impact performance of glass fiber reinforced nylon 6 materials will be improved.Some glass fiber reinforced nylon 6 surface cracks are not prone to occur.

One is that the tensile mechanical properties of glass fiber reinforced nylon 6 are improved, but there are several shortcomings: the existence of the candle wick effect will reduce the flame retardant performance.

Second: the appearance and transparency of glass fiber reinforced nylon 6 decrease, and the problem of floating fiber affects the use of glass fiber reinforced nylon 6.

Third: the processing performance of glass fiber reinforced nylon 6 will drop sharply, the fluidity will become very poor, and the injection pressure will increase a lot compared to when no glass fiber is added.When the fiber is used, it should be increased by 10°C to 30%°C.

But how to take advantage of glass fiber reinforced nylon 6 in injection molding: the glass fiber diameter of glass fiber reinforced nylon material is generally controlled between 10 and 20 microns.

Second: some coupling agents can be added appropriately, so that the impact strength of the notch can be increased with the increase of coupling agents.

Third: It can eliminate some moisture on the surface of glass fiber reinforced nylon 6, and then some hydrolysis reactions generated by glass fiber reinforced nylon 6 can be degraded during the melt extrusion process, thereby effectively reducing the glass fiber reinforced nylon 6 material.mechanical properties.

Fourth: But you can also control the length of the glass fiber, generally it is better to control it at 2 to 3 mm.

The longer the glass fiber reinforced nylon 6, the better the material properties, but the surface of the glass fiber reinforced nylon 6 material is rougher., but the warping problem is more difficult to control.